Steel springboard with M18 bolt hole. For plate and plate connection, adjust the bottom width of the platform. Between the steel and steel springboard springboard, using height of 180mm baseboard skirting board, paint black and yellow, the fixed baseboard with screws in 3 holes in their. The steel springboard and the steel springboard can be fixedly connected. After the completion of the connection, should be strictly on the production platform for acceptance of materials, the platform is completed, the test. The installation is completed, and can be put into use only after acceptance. Steel springboard steel springboard is a kind…

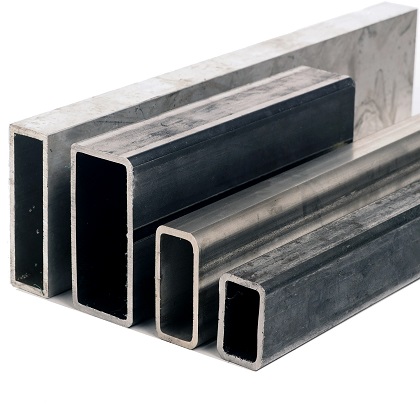

Cold galvanized square pipe is galvanized, the amount of zinc is very small, only 10-50g/m2, the corrosion resistance of its own specific galvanized pipe difference. Regular galvanized pipe manufacturers, in order to ensure quality, most do not use electro galvanized (Leng Du). Only those small scale, obsolete equipment of small enterprises using zinc plating, of course, their prices are relatively cheap. At present, the Ministry of construction has been officially below, the elimination of backward technology of cold galvanized pipe, the future is not allowed to use galvanized pipe for water, gas pipe. Generally speaking, the diameter of the pipe…

Solvent-free epoxy coating excellent corrosion resistance, durability, wear resistance, mechanical strength and other aspects have obvious advantages, compared with the traditional solvent-based coating with edge coverage is good, easy to produce cracks, high construction efficiency, construction The safety of better features, so that solvent-free epoxy coatings are increasingly widely used in large galvanized pipe corrosion. At present, for large-scale galvanized pipe solvent-free coating applications are mostly artificial coating method, the quality of the coating can not be guaranteed, low efficiency, coating curing time is long, need to occupy a large number of venues. In view of this situation, developed a…

First, galvanized square tube and fixture should be removed before the heat treatment of oil, residual salt, paint and other foreign objects; Second, the first used in the vacuum furnace fixture, should be no less than the required degree of vacuum in the work under the degassing purification; Third, deformation of the workpiece in the heat treatment process, should be heated on a dedicated fixture. Preheating methods are: a preheat to 800 ℃, the second preheating to 500-550 ℃ and 850 ℃, a warm-up speed should be limited; Fourth, for complex shapes or sharp changes in section and the effective…